This course provides an opportunity for students to become familiar with the

acts, rules and regulations in the Occupational Safety and Health

Administration Act 1994 (OHSA 1994) . Students will be exposed to the safety

and health procedures, rules and techniques to improve the work place.

This course provides students with knowledge and understanding of piping technology, which include from basic material selection, installation, applications for specific pipe material and types, sizes and also inspection method.

This course is intended to familiarize the participants with the key aspects of layout and design of process equipment and piping systems and to provide them with practical working knowledge in this very important field.

Key considerations in the layout and design of process equipment and piping systems include operability and maintainability as well as safety and environmental implications and compliance with applicable regulations, codes and standards.

The process of reverse engineering has proven infinitely useful for analyzing Original Equipment Manufacturer (OEM) components to duplicate or repair them, or simply improve on their design.

This course introduced the students regarding the basic fundamental of fluid mechanics and thermodynamics. Also, this subject exposed the students regarding the First and Second Law of Thermodynamics, Bernoulli’s equation and how they relate to system applications. Several calculations and experiments will be involved in this module.

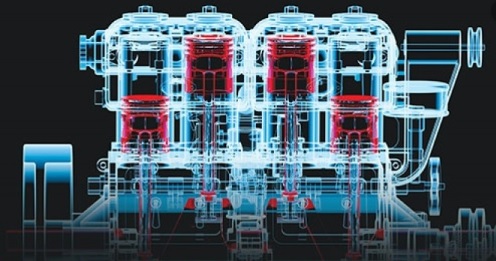

This course provides students with knowledge and understanding of rotating equipment and their auxiliary functions. It covers electrical and mechanical aspects by means of theory and practical hands-on to proper operation, troubleshooting and corrective actions. The students will be exposed to the analysis vibration surveys in forecasting and monitoring machines and applications behavior.